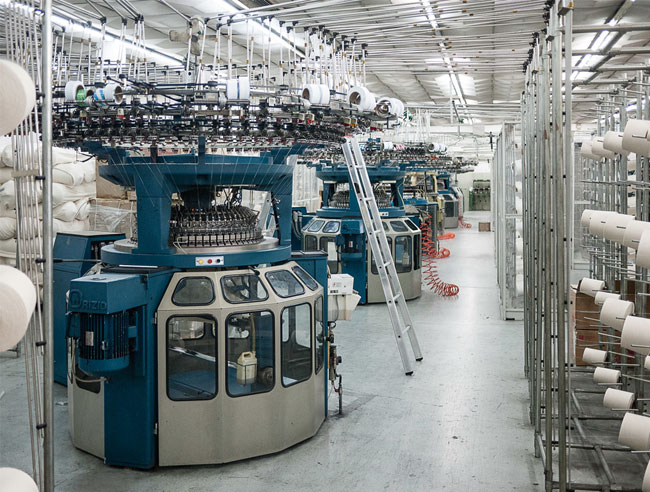

At present we have two state of the art apparel manufacturing facilities in Tamilnadu India, each equipped with the latest machinery, managed and run by highly skilled employees Our current industrial set up allows us to house 300 machines with a total installed production capacity of 1 5 Million pieces per annum Under the guidance of the management, there is a continuous effort to upgrade to the latest technology at our manufacturing facilities Technology such as the C A D and E R P Software, not only helps us in reducing production times, but also in improving the quality of the finished product.

Machinery as one of the leading clothing manufacturers of quality ready made apparel in India, our state of the art facilities boast an impressive array of manufacturing equipment over 300 machines at present Both facilities provide JRAJ with a combined installed capacity of 1 5 million pieces per annum.

Some of these machines installed in various sections on the production floor include:

JUKI & BROTHER make Single Needle Programmable UBT Machines Wastema Band Knife used in the Cutting & Finishing Sections Metal Detecting Machines All procurements are from some of the world's best brands such as Brother, JUKI, Pegasus, Kansai, Hashima, Yamato, Wastema, and Ramsons.

- 145 JUKI & BROTHER Single Needle Machines

- 105 JUKI & YAMOTA Overlock Machines

- 50 JUKI & Pegasus Flatlock Machines

- 4 Juki Button hole and attaching Machine

- 5 Kansai Special Purpose machines